ENGLISH

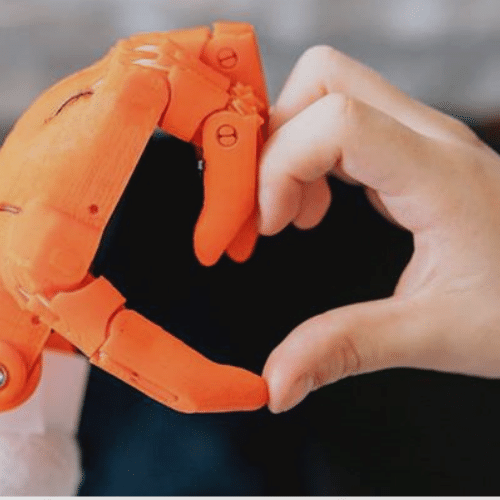

Hands on

There are more kids born without hands, forearms and arms than most people realise. There are also many kids who have lost limbs due to an accident or illness. These kids are left without help because they grow too fast to be able to use expensive and complicated prosthetic arms.

We want to fill this gap with simple and quickly delivered prosthetic arms free of charge, produced on 3D printers. Arms that can be replaced year by year as kids grow. The actual cost of producing one prosthetic arm with our method is very low – between 25 and 100 USD.

Raised: $34k

of $50k Goal

Why we started

The project was created by Julian – a desperate father seeking help for his son Ben who was born without most of his left arm. Very quickly Ben’s family realised that it would be impossible to provide him with a prosthetic arm – they are too expensive, too delicate for a normal active child and would need to be replaced too often. We also discovered that what kids really want and need is not always what we think. They do not usually want realistic looking prosthetics, but rather something more interesting; bright, colourful, robots, pirates, Ironman, Spiderman etc.

Children without arms and hands often feel they are lacking something compared to their colleagues at school and kindergarten. With the right prosthetic, the child can feel they have something their friends will even be jealous of, they could become a superhero. This is very important for the psychological development of the child.

And so, from these realisations of what children need, the Hands On project was born – made-to-measure, fast to make, brightly-coloured prosthetic arms and hands for kids that are so cheap to make they can be replaced regularly and given away to children for free.

In addition to universal natural arms, dedicated designs are also possible:

a hand to be used to riding a bike

a hand to help holding a pen

a hand to help typing

a hand to help holding a book or a cellular phone

a hand to help using a gamepad

a hand to help gluing models etc

a hand to help play a musical instrument

a hand to help … whatever a kid wants to do

Because the project is so inexpensive it is possible to deliver more than one prosthesis per child.

How we do it

• We interview the child and the parents to learn their needs and to find a common understanding of what can be done, to use technology to the limit and to avoid disappointment (see requirements for first-contact agent).

• Take measurements of the hand or arm to prepare the project. Every one of the prosthetics is different and is made to measure for the needs of the individual child. (measuring agent).

• Modify existing projects based on actual measurements or requirements (design agent).

• Print an actual prosthetic arm (production agent). This takes between 4 and 24 hours.

The whole process from measurements to delivery could be finished in as little as 4 days.

What we are looking for

We can print hands only for a very few kids, so we are looking for Rotary Clubs around the world to join us and produce and deliver prosthetic hands to kids in need in their local area.

We do this for free and we expect that our partners will provide the prosthetics also for free, without any hidden costs.

How to be a partner

1. Find a child in need of a prosthetic arm or hand.

2. Find someone near you with a 3D printer (see requirements below) who is willing to contribute time for the use of their printer. Such printers are very popular and also often not very extensively used.

3. Contact hands-on@rotarysopotinternational.org for help

4. See requirements section.

What is our goal

We will be happy to share for free our experience, knowledge and training to make this project available in new locations.

We also will consider providing a dedicated communication infrastructure for a central repository of projects to be easily reused around the world, and to provide communication medium for partners to exchange ideas (when the project grows). We could call this a kind of Center of Competence.

Requirements

A committee will need to be set up, with one or two people prepared to operate the printing process and at least one other person who will be the designated contact for the people who require the prosthetics.

FIRST-CONTACT AGENT and MEASURING AGENT

Responsibility

To interview the child, notify parents about the process, organize and carry out measurements etc. To provide reliable measurements for sizing the prostheses. There is considerable help and established models which have simplified the measuring and sizing process. We will also provide help and guidance how to do this.

Requirements

Some training (from us) will be required, although no special qualifications are required, anybody can learn to do this.

DESIGN AGENT and PRODUCTION AGENT

Responsibility

To design a prosthesis on a 3D Printer based on existing designs which are available through open source projects; to update modified designs to a shared repository.

To produce actual prosthesis on a 3D Printer

Requirements

Access to a 3D printer, experience in 3D printing.

Equipment

We use a typical 3D printer with a market price of only around 1000 EUR. Our printer (Prusa MK3S) has a printing volume of 25x21x21 cm and a precision of 0.05mm.

850g of PLA (polylactic acid) material, used as the filament, costs approx. 25 EUR.

go to manual in english

AMBASSADORS

![]() We have ambassadors all over Poland who you can contact to hear more about the Hands On Project.

We have ambassadors all over Poland who you can contact to hear more about the Hands On Project.

![]() Mamy ambasadorów w całej Polsce, z którymi możesz się skontaktować, aby dowiedzieć się więcej o projekcie Hands On.

Mamy ambasadorów w całej Polsce, z którymi możesz się skontaktować, aby dowiedzieć się więcej o projekcie Hands On.

Julian Gilbert email: northern-poland-ambassador@rotarysopotinternational.org

RC Gdańsk Centrum, RC Gdańsk-Sopot-Gdynia, RC Gdynia, RC Gdynia Orłowo, RC Słupsk, RC Sopot, RC Sopot International.

Bartłomiej Jarkiewicz email: warszawa-abassador@rotarysopotinternational.org

RC Warsaw, RC Warsaw Belvedere, RC Warsaw City, RC Warsaw Fryderyk Chopin, RC Warsaw Goethe, RC Warsaw Józefów, RC Warsaw Konstancin, RC Warsaw Sobieski, RC Warsaw Wilanów, RC Warsaw Żoliborz

Tomasz Kosinski email: international-ambassador@rotarysopotinternational.org

RC India, RC Nigeria

David Bulnes Abundis email:engineer_hands_on@rotarysopotinternational.org

Developer, 3D printing, technical issues.

Ewa Okrucińska email: editor_hands_on@rotarysopotinternational.org

donate

PKO Account No.:

PLN: 92 1440 1026 0000 0000 0289 1198

EUR: PL 40 1440 1026 0000 0000 1410 1454